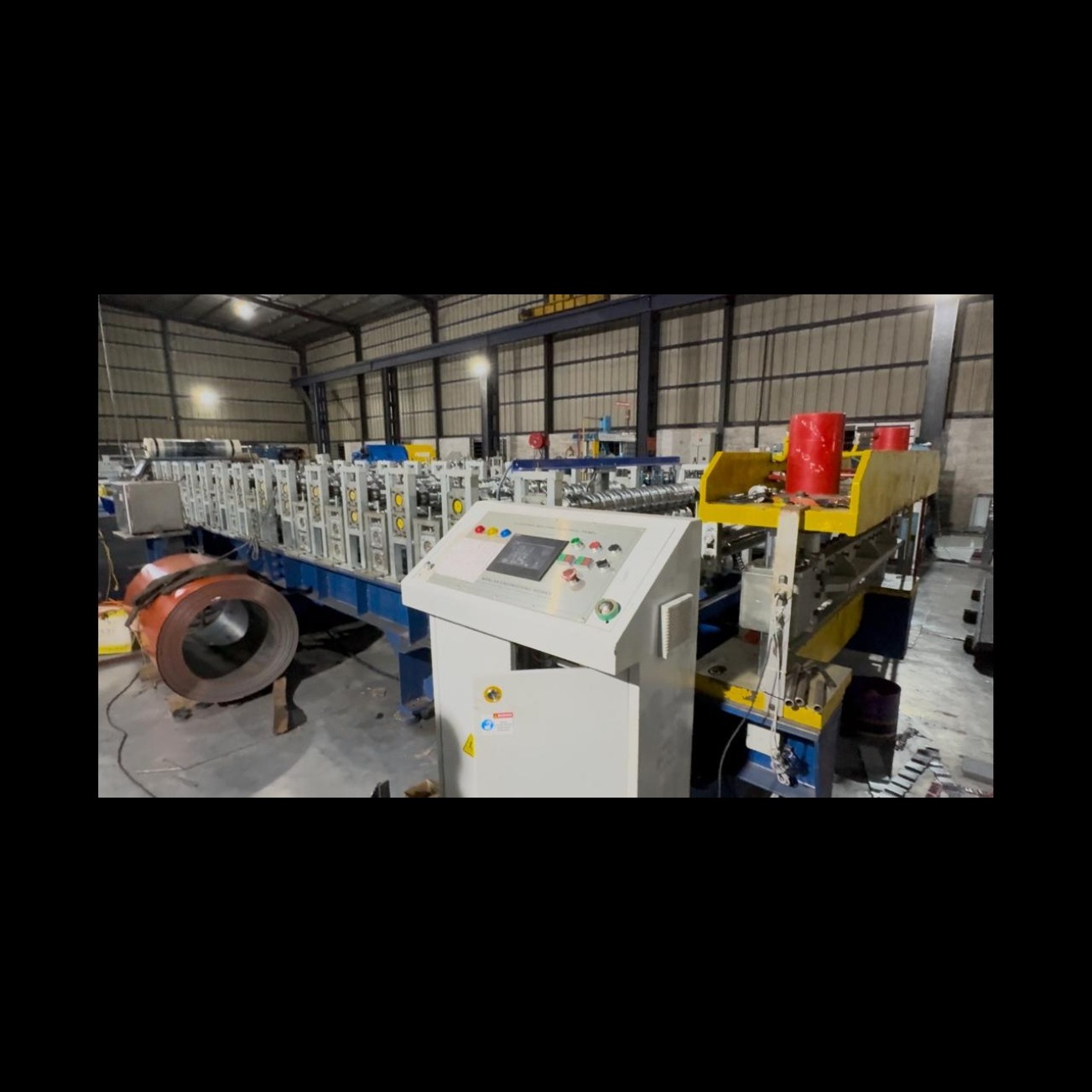

We are very happy to introduce our self to an esteemed organization of yours: ours is proprietorship firm and an exporter based within the easily accessible industrial estates of Coimbatore (Tamil Nadu). We are actively engaged in manufacturing and exporting in a widespread range of quality Roll Forming Machine in Coimbatore, Tamilnadu, South India. Over a span of time, we have grown as a full-fledged organization offering world-class Roll Forming Machinery to our global clients. This became possible due to the painstaking efforts undertaken by our workforce and the assistance of our high tech manufacturing facilities. Other Searches Roll Forming machine manufacturers in Coimbatore India Top 10 Roll Forming Machine Manufacturers in Coimbatore India New Roll Forming Machine Price in Coimbatore India Top roll forming machine manufacturers in Coimbatore India Roll Forming Machine Manufacturers in Coimbatore India Roll Forming Machine – Overview A roll forming machine is a type of industrial equipment used to continuously shape metal sheets or strips into a specific profile (shape) by passing them through a series of precisely positioned rollers. Think of it like a pasta machine for metal — you feed in a flat strip, and it comes out in the desired shape. How It Works Material Feeding A coil of metal (steel, aluminum, copper, etc.) is loaded into a decoiler. The strip is unrolled and fed into the machine. Roller Stations The machine has multiple roller stations (pairs of rollers) arranged in sequence. Each station bends the metal slightly — the shape is formed gradually to avoid cracks or deformation. Cutting After forming, the profile is cut to the required length. Cutting can be post-cut (after forming) or pre-cut (before forming). Key Components Decoiler – Holds and unrolls the coil. Roller Stations – Shape the metal step by step Drive System – Powers the rollers Cutting Unit – Cuts the formed profile. Control System (PLC) – Automates the process and maintains accuracy. Advantages High-speed, continuous production. Consistent quality and precision. Minimal material waste. Can produce complex shapes. Common Products Made Roof panels & wall claddings. Door & window frames. Cable trays. Guard rails. Shelving & racking sections.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.maklanengineering.com/latest-update/best-price-roll-forming-machine-manufacturers-in-coimbatore/10

Best Price Roll Forming Machine Manufacturers in Coimbatore

2025-08-08T12:21:01

We are very happy to introduce our self to an esteemed organization of yours: ours is proprietorship firm and an exporter based within the easily accessible industrial estates of Coimbatore (Tamil Nadu). We are actively engaged in manufacturing and exporting in a widespread range of quality Roll Forming Machine in Coimbatore, Tamilnadu, South India. Over a span of time, we have grown as a full-fledged organization offering world-class Roll Forming Machinery to our global clients. This became possible due to the painstaking efforts undertaken by our workforce and the assistance of our high tech manufacturing facilities. Other Searches Roll Forming machine manufacturers in Coimbatore India Top 10 Roll Forming Machine Manufacturers in Coimbatore India New Roll Forming Machine Price in Coimbatore India Top roll forming machine manufacturers in Coimbatore India Roll Forming Machine Manufacturers in Coimbatore India Roll Forming Machine – Overview A roll forming machine is a type of industrial equipment used to continuously shape metal sheets or strips into a specific profile (shape) by passing them through a series of precisely positioned rollers. Think of it like a pasta machine for metal — you feed in a flat strip, and it comes out in the desired shape. How It Works Material Feeding A coil of metal (steel, aluminum, copper, etc.) is loaded into a decoiler. The strip is unrolled and fed into the machine. Roller Stations The machine has multiple roller stations (pairs of rollers) arranged in sequence. Each station bends the metal slightly — the shape is formed gradually to avoid cracks or deformation. Cutting After forming, the profile is cut to the required length. Cutting can be post-cut (after forming) or pre-cut (before forming). Key Components Decoiler – Holds and unrolls the coil. Roller Stations – Shape the metal step by step Drive System – Powers the rollers Cutting Unit – Cuts the formed profile. Control System (PLC) – Automates the process and maintains accuracy. Advantages High-speed, continuous production. Consistent quality and precision. Minimal material waste. Can produce complex shapes. Common Products Made Roof panels & wall claddings. Door & window frames. Cable trays. Guard rails. Shelving & racking sections.

2025-08-08T12:21:01

Submit Your Enquiry